When the 3D fabric is impregnated with a thermo set resin ,the fabric absorbs the resin and rises to the preset height.

The Resin/fabric content weight ratio 1:1, curing agent: MEKPO 1.5-2%.

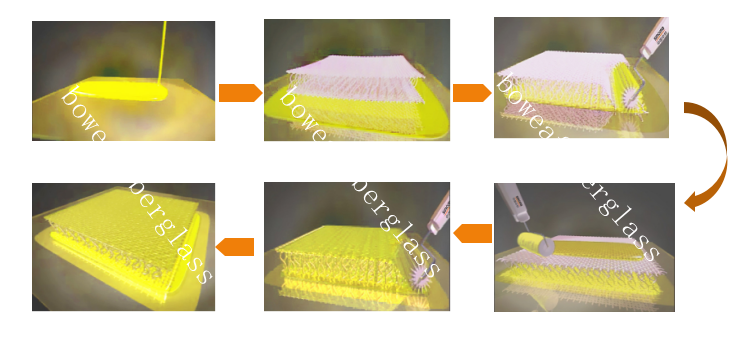

Mainly there are two ways of process we can laminate.

1.Hand Lay-up

Step1: Apply 50% of the resin on the smooth surface of mold and distribute it evenly.

Step2: Apply the 3D fabric into the resin

Step3: Roll the fabric firmly but gently along the weft direction to secure a good contact with the resin underneath.

Step4: Evenly apply the remaining 40% of the resin over the fabric and distribute it evenly

Step5: Roll resin gently into the fabric. The capillary forces of the vertical piles will impregnate the fabric and rise into the preset height.

Step6: After cured ,a piece of 3D composite is formed.

Find more product details on: http://www.boweafiberglass.com/35-3d-glass-fabric