High silica fiberglass is the abbreviation of high-purity silica amorphous continuous fiberglass, in which the silica content is more than 96%, the continuous working temperature is 1000 degrees Celsius, and the short-term temperature is 1400 degrees Celsius.

High silica fiber can maintain good strength and elasticity for a long time at 1000 degrees Celsius. It is an effective thermal barrier for ultra-high temperature heat flow and jet flame, and a reliable protection device for personnel facilities. The high silica fiber also has low thermal conductivity and good resistance to high thermal shock.

The performance of high silica products is inert to most chemicals. It has good corrosion resistance to high temperature compounds, corrosive minerals and weakly alkaline molten alloys. It can work normally under high heat and strong radiation conditions.

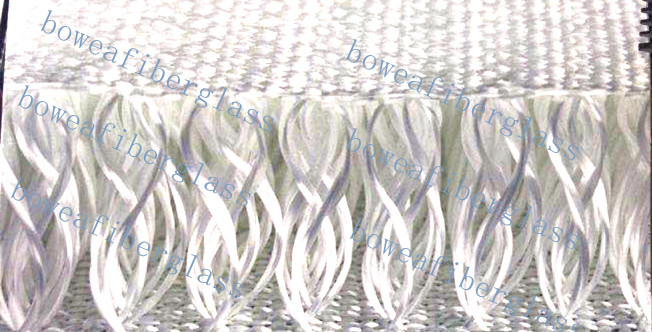

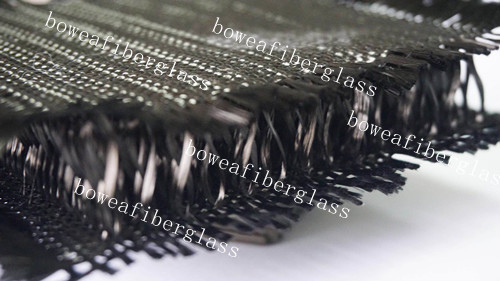

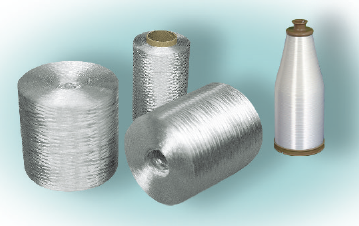

The high silica products mainly include continuous yarn,woven rope, sleeve, fabric, chopped strand mat,stitched fabric, mainly used in 1000 degree ultra-high temperature fire insulation, single fiber diameter mainly 6 um to 9 um, does not contain any asbestos or ceramic wool, completely harmless to health.

At present, it has been widely used in spacecraft heat-resistant ablation materials, high-temperature insulation, high-temperature gas dust collection, liquid filtration, metal melting filtration, purification, etc.

Find more products on : http://www.boweafiberglass.com/41-high-silica-fiberglass